Key aspects for the sustainable use of groundwater to meet industrial water demand

/Following the term “applied hydrogeology for non hydrogeologist” we found that little has been made to bring practical and scientific-based concepts to professionals from other areas (and for the common people as well). Hydrogeology itself seems to be an area with a variety of “flavours” where the knowledge of groundwater resources has “trends” based on authors, disciplines or tools, however, there is a common characteristic in the study of groundwater resources worldwide: hydrogeological evaluations are expensive, take a lot of time and deal with a high degree of uncertainty.

Hydrogeologist need to support the industry in a modular manner where hydrogeological concepts and evaluations has to be understood by all the related stakeholders in order to conduct an industrial activity with a clear sense of pumping / water level performance and changes in water quality with time.

Popular hydrogeology and decision making

Even though the decisions about the groundwater use can affect the feasibility of an industrial plant, the common background and understanding of how an aquifer works remain very poor among the project and planning personal. That scenario would bring an interesting question: If few people know exactly how an aquifer will perform on the future, how a team plans the water supply of an industrial activity?

Key aspects

This article brings some key aspects to take into account on the decision making process for the planning and project phase of an industry based on groundwater supply.

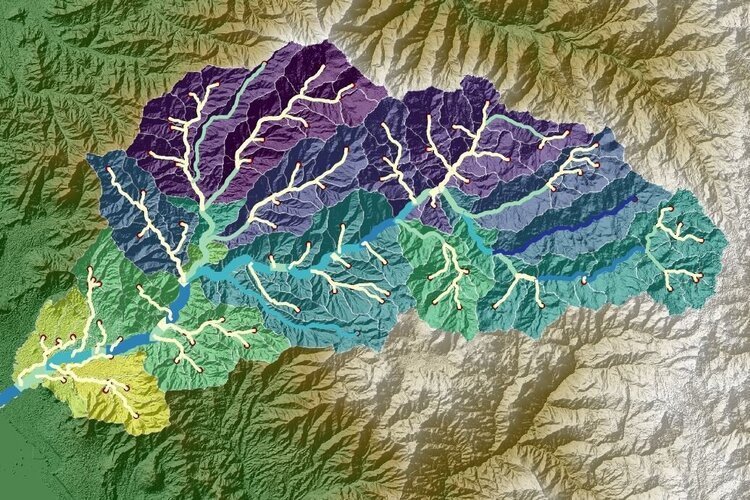

Aquifer sustainability: Let's say that an aquifer is a dynamic reservoir and you plan to extract from this reservoir, but how much water can you pump?. Will you extract water or mine water? The answer to this question requires to look on the inflows to the groundwater flow regime, that is usually recharge from precipitation but it can be recharge by irrigation, the interaction with a lake or river, among others. The amount of water that you can pump cannot be greater that the amount that enters the system otherwise you will be mining the aquifer and pumping wells will show a decreasing trend of water levels and potentially they well will dry.

Porous media: An aquifer is a dynamic reservoir, but the dynamic is a particularly slow. Travel paths on the groundwater flow regime can take weeks, months, years of decades. The porous media regulates the maximum amount of water that an industry can pump, if the hydraulic conductivity of the porous media is high (case of gravel or coarse sand) the amount of available water for pumping will be higher than in the case of silt or clay.

Extraction method: Sometimes an industry cannot pump all the required water not because the aquifer is unable to supply the demand, but because the design of the extraction method is wrong. In order to increase pumping flow, wells need to be as deep as possible, screened on most of the wet depth and with the well installed at well bottom.

Aquifer water quality: Salinization or contamination can pose threats to industrial water demand. Usually freshwater is located on the upper parts of the aquifer, whereas more saline water is located on the bottom part of the aquifer. Pumping bring fresh water on the beginning but the dissolved solids concentration (TDS) can increase with time when pumping interacts with the lower horizons of the aquifer.

Social licence: Industrial use of the aquifers will bring impacts on the neighboring users, usually these impacts are a decrease in water level. The assessment of this decrease have to be done prior to the operation to conduct social programs, run workshops and create strategies on the social networks.